Main Duties and Responsibilities of the company

As part of the EIGR contract, CSL did a comprehensive survey of a large number of sites. On numerous sites, it was found that the control panels were in a very poor condition, they were unsafe, unreliable and beyond economic repair. Following the surveys, reports were issued by CSL’s engineers to Irish Water for each of the sites. Then workshops were held with Irish Water and scope of works were established. In many cases the scope required new control panels, new automation systems, telemetry and SCADA systems. Works are still on going on this contract; below are examples of the automation solutions that were designed, installed and commissioned by CSL’s in-house automation team, commissioning engineers and electrical design team as part of the EIGR contract:

Castle Island WTP

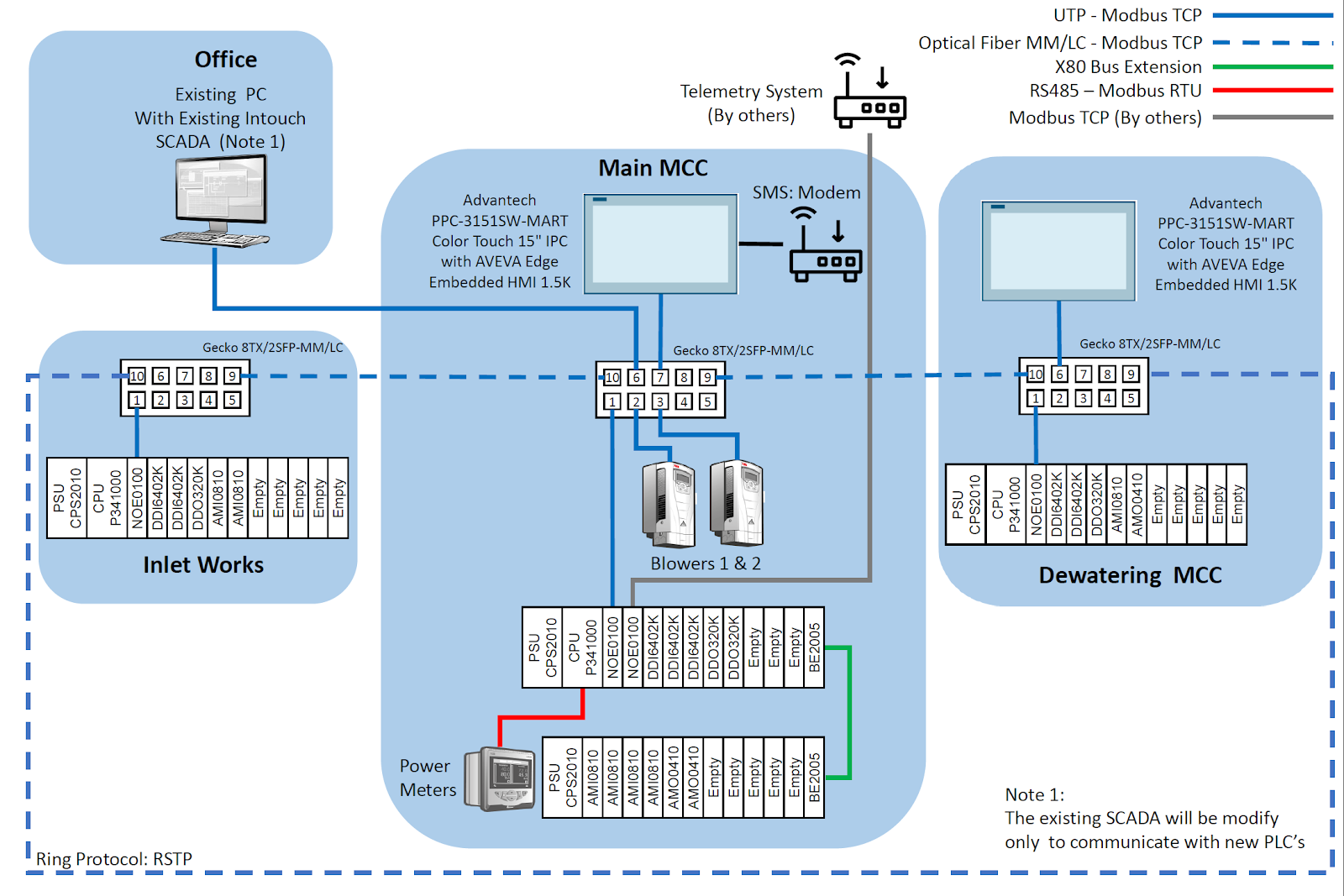

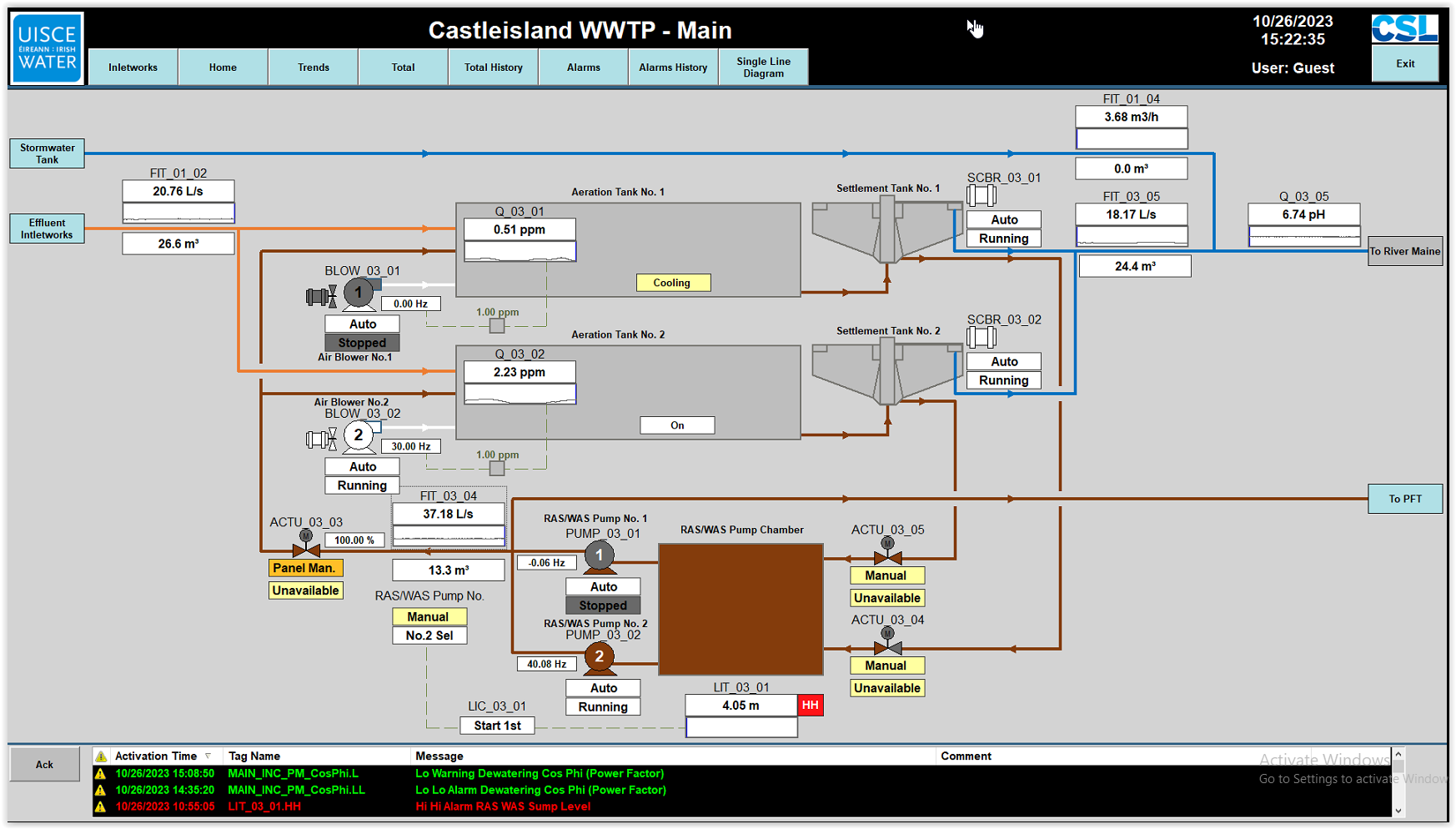

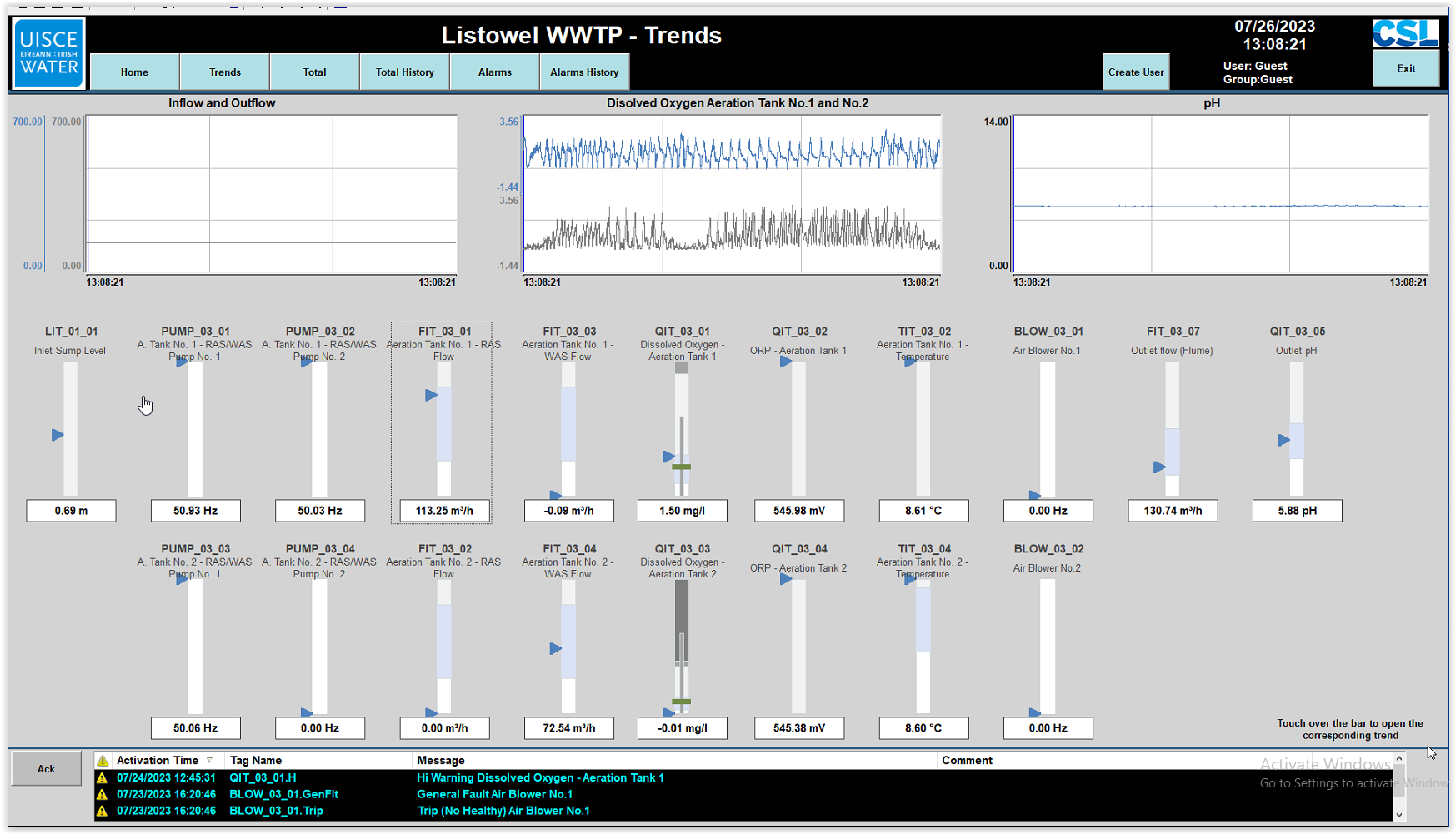

It was observed during the survey that the main control panel was in a very poor condition. Furthermore, fire damage was discovered; the Dewatering control panel was condemned mainly due corrosion damage. To date a new control panel has been designed, installed and commissioned as a replacement for the old one. The new control panel came complete with an upgraded automation system to control the existing equipment. A new PLC with I/O and a local SCADA was installed. A new PLC program was developed to control all the equipment and instruments in this panel. A fibre optic ring network was installed to allow all the devices on the automation system to communicate with each other. The automation solution used for the new control panel was based around hardware from Schneider Electric using the M340 PLC. A five thousand tag Avea Edge SCADA system was installed on an industrial panel PC complete with a 15″ colour touch screen. The SCADA software provides comprehensive graphics, archiving reporting and alarming. The graphics provide a real-time animated view of the status of all monitored IO while the trending delivers a reporting tool which provides the user with real-time / historical view of all the data from the plant’s instrumentation. All data is archived and logged onto the industrial panel PC’s hard disc. An SMS system is installed on the industrial panel PC which monitors the alarms generated by the facility and broadcasts the critical alarms to the plant’s operators and engineers via mobile phone SMS messages or emails. The existing on site SCADA system was also modified to allow it to communicate with the new MCC while the works were in progress to ensure no data was lost during the changeover.

Listowel WWTP

Similar to Castle Island, the agreed scope of works for Listowel WWTP included a new main control panel that has been designed, installed and commissioned as a replacement for the old one. The new control panel came complete with an upgraded automation system to control the existing equipment. When designing the control system for Castle Island and Listowel standardization played a vital role in the development of the PLC software and the SCADA system. Standardization made the process of upgrading easier and faster. Furthermore, the standard design makes it simpler and cheaper to maintain and operate the plants into the future. The same Schneider Electric M340 PLC hardware that was used in Castle Island was used in Listowel. Likewise with the SCADA system, a five thousand tag Avea Edge SCADA system was installed on an industrial panel PC. Again, a SMS system was provided on the industrial panel PC.

The rational for selecting the Schneider Electric hardware and the Avea Edge software was that this equipment is widely supported in Ireland by numerous system integrators in the water / wastewater industry.

East Gate Pumping Station

At East Gate Pumping Station, the initial survey found that the existing control panels were in a very poor condition. The wiring was untidy, the controls were fragmented. There were no drawings available on site for the panels. Many modifications were made to the panels throughout the years which made the panels dangerous and unreliable. The control circuits were 220VAC. A new distribution panel was installed in a new location to replace four smaller control panels. A new ICA panel was installed to house the automation and instrumentation equipment. The automation system used at this site was based around the Siemens S7-1200 platform. Rack mounted expansion IO modules were also included. A 10” HMI was provided on the ICA panel’s door. A SMS dial-out unit was provided. Due the size of the site it was a local SCADA system was not justified. However, the new system was configured to communicate with the existing radio UHF modem so that the necessary data was still available on the existing SCADA system.

Standards & Specifications

- The works above were caried out in accordance with the following standards and specifications:

- Water Industry Mechanical and Electrical Specifications (WIMES)

- Telemetry Outstations IW-TEC-400-002

- Automation and Control IW-TEC-400-003 DMA Data Loggers SCADA and HMI IW-TEC-400-001

- Handover Specification IW-TEC-600-05

- All the automation systems solutions provided are preconfigured for the future connection to the National Telemetry System