Quality

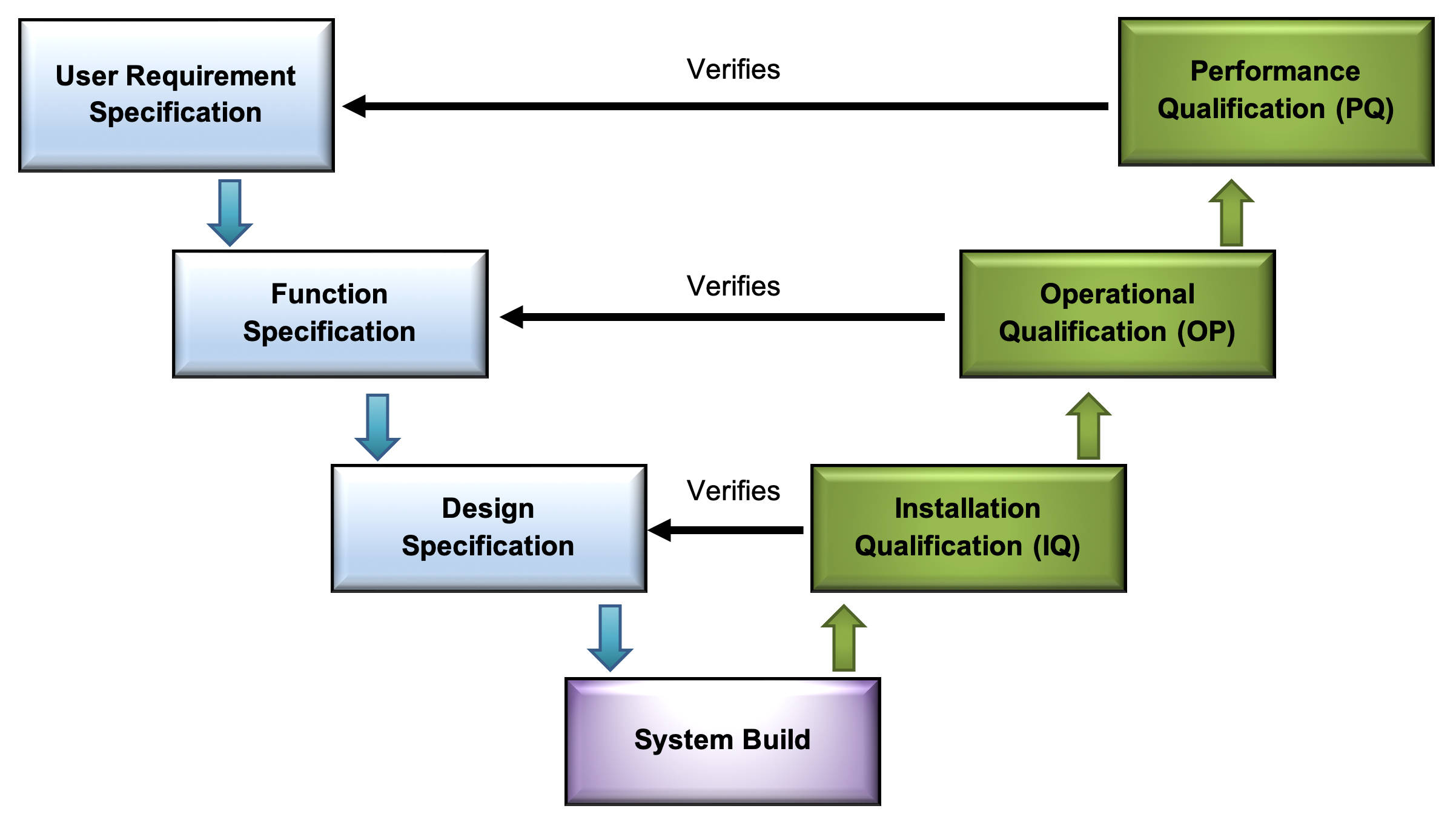

CSL engineering team will develop the automation system for this project using the GAMP (Good Automated Manufacturing Practice) guidelines. GAMP ensures that the highest quality is achieved and that the system is rigorously tested in an efficient and effective manner. The V model will be used for the development of the automation

Future Proofing

CSL’s designers include the following consideration when designing an automation system:

- Lifecycle – The lifecycle of PLC hardware can vary depending on the manufacturer and the specific product; CSL select the automation platforms that offer extended support for their products.

- Open Standards – The use of modern protocols such as Ethernet (eg. Modbus TCP, DeviceNet and the PROFINET) is chosen over older technology like serial to future proof the design. These protocols are publicly available and can be used by anyone to develop products or services. The protocols support high- speed connections, are scalable and integrates easily with other devices. Open standards allow for the integration of new technologies and components into the control system without having to replace the entire system. The Open Standard also makes it easier to upgrade the system without relying on a single vendor.

- Modular Design – The modular design of the system allows components to be easily added or removed from the system making it easier to upgrade.

- Reliability – Only hardware that have provide high reliability and availability are selected for CSL’s projects. The selected manufactures provide Mean Time Between Failure (MTBF) figures for all of their PLC modules which can be used to calculate the reliability of the system.

- Support – The materials used by CSL are widely available and are sold through numerous venders. The hardware is widely support by many system integrators in Ireland.

When designing automation systems, CSL selected software licences with plenty of spare capacity to allow for future expansion. In the region of 30% spare IO capacity, additional rack space and sufficient room in the control panel are also allowed in the design to accommodate future expansion. The selected processors always have