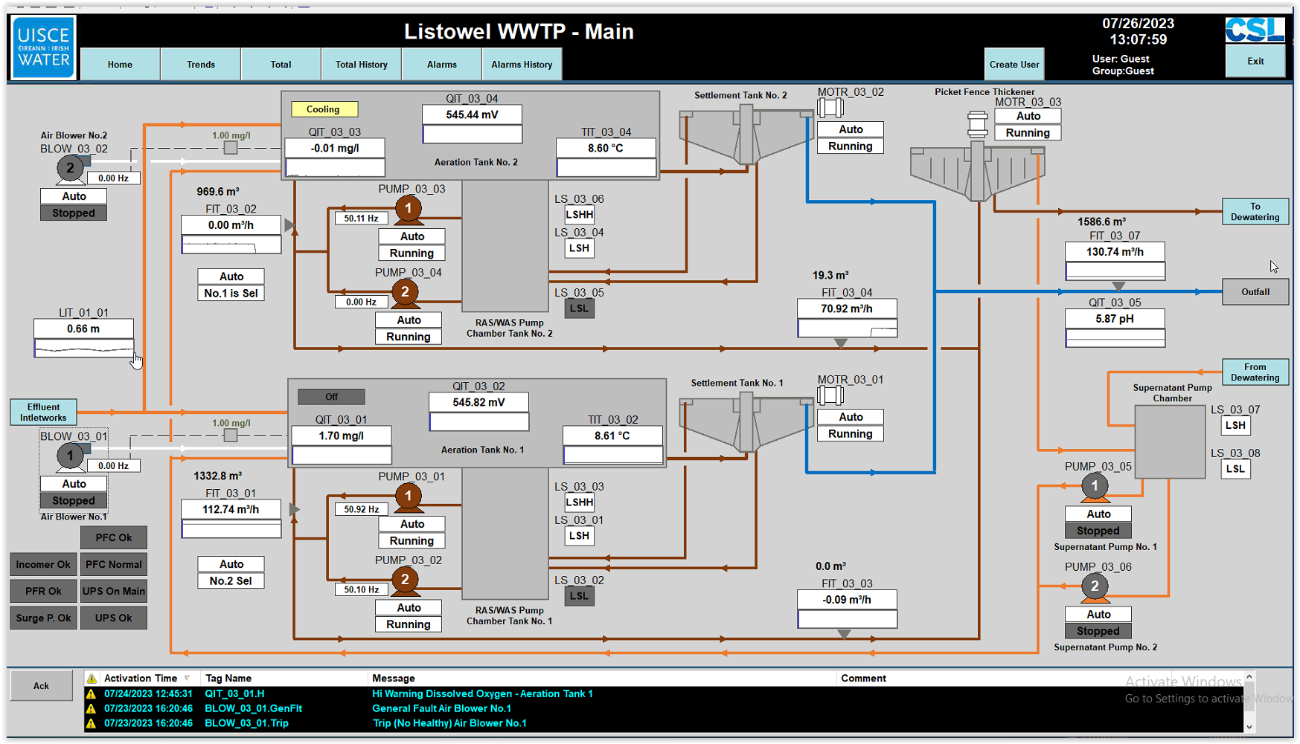

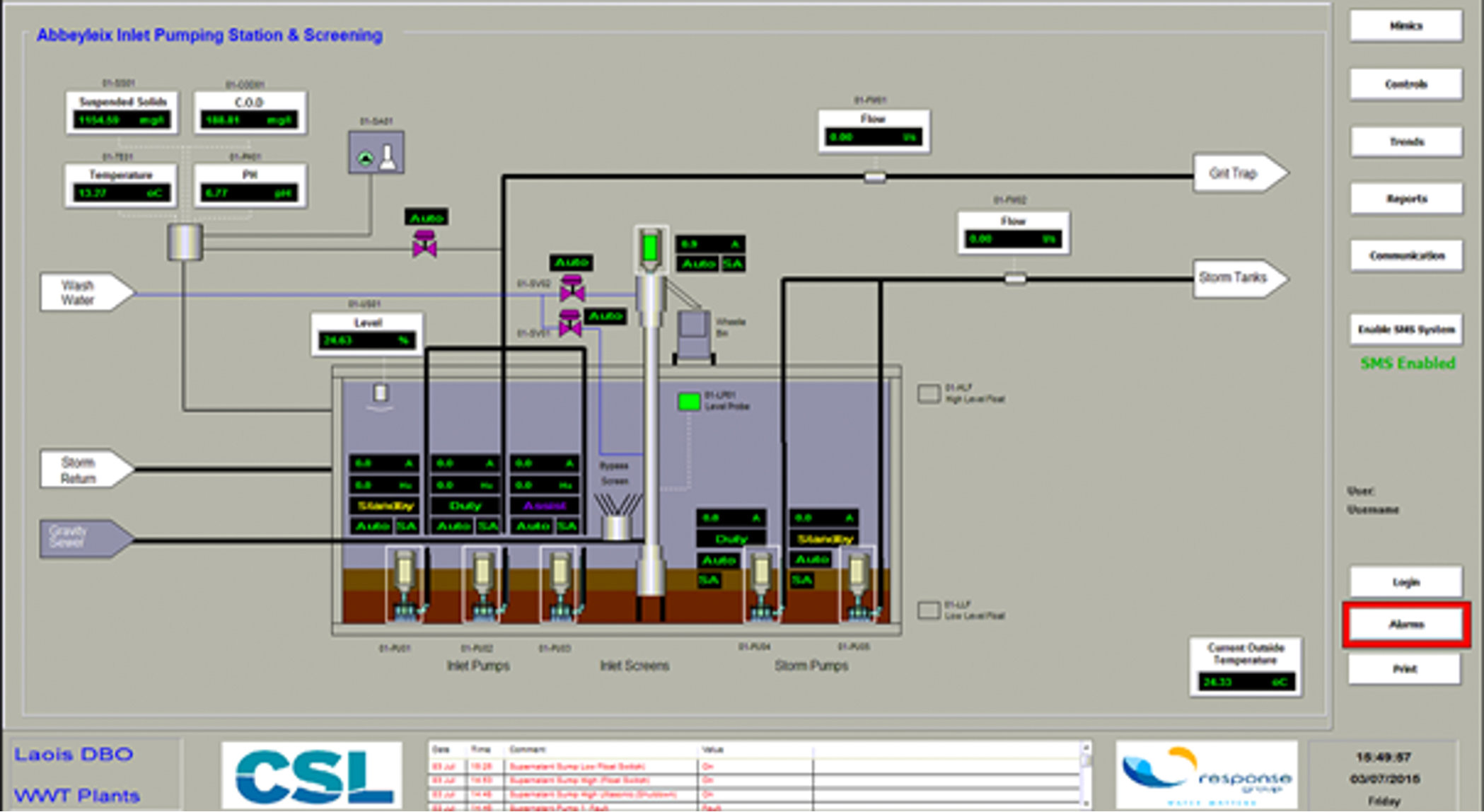

CSL provides visualisation systems, such as, standalone SCADA systems, web-based SCADA systems and HMIs. Using our visualisation systems the operator can view comprehensive reports, graphics and alarms. Our systems can send alarm notifications to the operator via email, voice recorded messages or SMS messages. CSL’s systems allow the operator to view and change the operational parameters for the control systems either locally or remotely via the internet. Furthermore, our user friendly real-time and historical trending provides the user with access to all the data associated within the control system. At CSL, we specialize in implementing High Performance HMI (ISA 101-compliant) HMIs for various industries. Our team of experts combines technical proficiency with a deep understanding of user experience to create interfaces that empower your operators and enhance productivity. Whether you are looking to revamp your existing HMI or build a new automation system from scratch, we have the expertise to design, develop, and implement solutions tailored to your unique requirements.

The SCADA systems provided by CSL include maintenance notifications for when a piece of equipment exceeds a maintenance run-hour service interval. These notifications are used to inform the operator to when a piece of equipment is due for a service. The number of starts of motor and the operating hours are also logged to help with maintenance. Critical parameters such as temperature, oil seal, VSD temperature, etc are monitored via the SCADA and an alarm is generated if a fault condition happens. The automation system also monitors critical panel components such as surge arrestors, phase failures and UPS faults. Automatic detection of instruments faults, using broken wire detection and mA monitoring is also provided. The selected PCs used by the SCADA systems have redundant solid-state drives to help protect the data, when data cannot be accessed, the redundant data can be used to replace or rebuild the missing data.

In CSL’s projects, the VSDs are networked to the PLCs so that additional information such as power, current, operating temperature, alarms are available to the SCADA system. This additional information is valuable for determining if the performance of a piece of equipment is deteriorating. An animated view of the automation system’s architecture is available on the SCADA system. The system architecture details IP addresses, the PLCs’ status, SCADA status and the telemetry links status. The system architecture screen is an important tool for diagnosing issues especially for engineers that may not be familiar with the site.